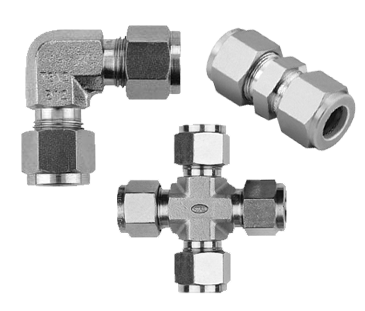

- Unique three piece design.

- Ferrule takes seat on pipe surface when tightened, thus provides leak proof joint.

- Case hardened ferrule for hard case and soft core for spring action and repeated use.

- Light, Medium and Heavy pressure class.

- Special Manganese based Phoaphatieing treatment of surfaces for corrosion resistance.

- Cadmium plated ferrule for self lubrication. while assembly.

- Special execution for Galvanised & Cadmium and Nickel plated finish.

- Metric and Inch series fittings.

- Strict quality check at each stage of manufacture.

- Hydraulic test for compliance for each batch. |